Product Details

Large high speed rotating equipment - gas and steam turbines; axial and centrifugal compressors - are the most widely

used power sources in the world today. In either primary or stand-by power mode, they are reliable and cost effective,

but require large volumes of mineral or synthetic oil for lubricating, cooling and sealing the bearings. When subjected to

the temperature and mechanical forces of the bearings,large volumes of mist and vapour result, creating a visible plume

from the lube oil vent.

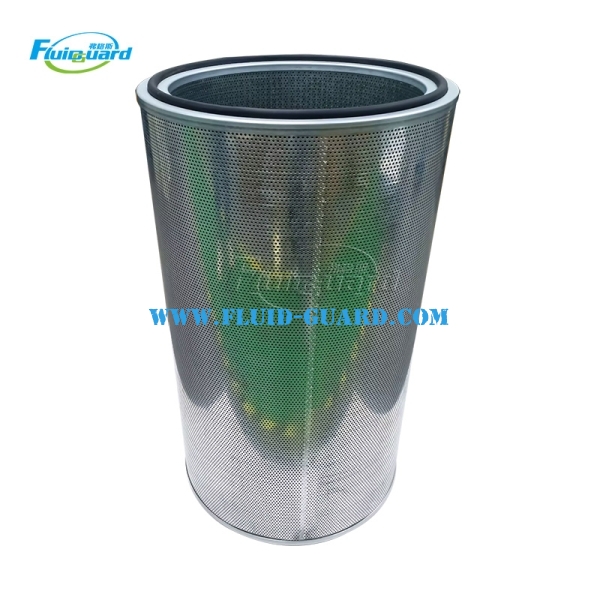

The Cleanova Oil Mist Eliminator (OME) is a highly efficient dynamically engineered filtration system for source control of

mist created by high speed rotating equipment. The product range includes both nonblower and blower assist models

for positive and negative pressure lubricating oil systems.

OE-158B Blower Assist Models

Many gas turbines and turbo compressors are designed to operate with the lube oil reservoir maintained at a negative pressure

(-25 to -100 mm W.C). When installing an oil mist eliminator on such systems, a blower assist model is used to overcome thedifferential pressure

of the the filter and, at the same time, keep the negative pressure in the reservoir under control.

OE-158 Non-Blower Model

With positive pressure systems there is usually sufficient pressure in the reservoir to overcome the

differential pressure (approx 460 mm W.C) of our mist eliminator.

OE-158 Non-Blower Model For positive pressure lubricating oil systems

Technical Data :

• Maximum operating temp:1750C

• Maximum recommended operating temp: 820C

• Minimum operating temp: -150C

Element Differential Pressure :

• Dry: 150mm W.C.

• Fully saturated: 460mm W.C.

Recommended Pressure Differential for

• Element change: 760mm W.C.

Dimension : 533*432*890mm

Zhengzhou Fluidguard Machinery Equipment Co., Ltd. TEL: 0086-0373-5128206

Zhengzhou Fluidguard is a collection of filter strainer, filter element, oil purifier and air compressor design and manufacturing, online sales and marketing as one of the modern manufacturers